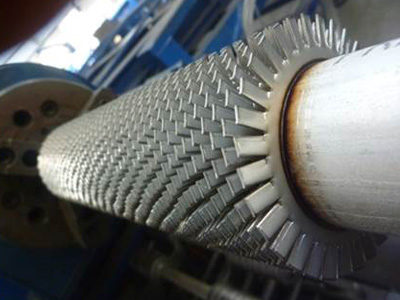

Laser Welded Finned Tubes

Finned tubes produced using laser technology are characterized by a continuous weld enhanced with a greater full penetration between the fin root and tube wall without any excess filler metal or unnecessary fin material (e.g. L-foot), with no “cold spot” promoting void between the fin root and pipe and maintains the shape of the fin root. By implementing laser welding technology, the result is a finned tube of extremely high quality along with increased productivity many times over that of the typically produced finned tube.

This is the first such implementation worldwide for laser welded fin tube. The manufacture of the tubes takes place on two automated cells integrated with line for anticorrosive protection and tube packaging after welding.