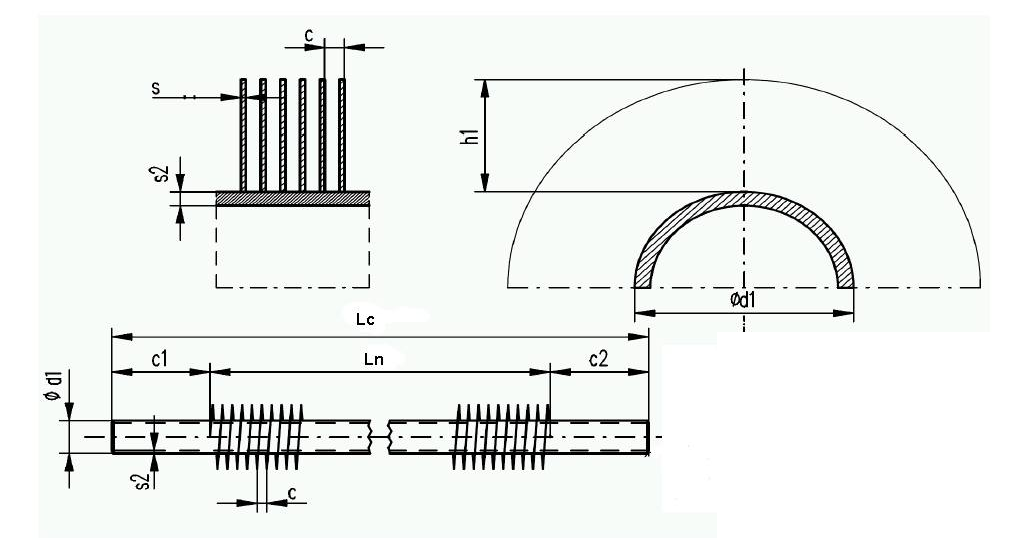

Typical Tube Dimensions*

Diameter: from 15 – 63.5 mm

Length: up to 21 m

Height of fin: up to 0.50 x tube OD

Fin thickness: 0.6 mm to 1.5 mm (serrated fin: max 1.2 mm)

Fins per inch/meter: up to 500 fins / meter (depends upon fin thickness)

Grade fin material: Carbon Steel, Inconel, Stainless Steel, inquire*

Tube material: Carbon Steel, Alloy Special Steel, CrMo, Inconel, inquire*

Imperial and metric units are acceptable

Standard documentation: English, German or Polish (other: please inquire)

*Please note: Alternate grades and requirements can be available. May require additional technological tests

Conditions of acceptance

Linear dimensional tolerance for tubes is according to EN ISO 13920 - class B

When drawings are supplied by the client, drawing tolerances will be in force

Tolerance of fin tubes (outside diameter: tube and fin): 0 +/- 2 mm. When drawings are supplied by the client, drawing tolerances will be in force

The following welding tolerances are acceptable:

L ≤ 5000 mm

Weld gap shall not exceed 2.5% per meter of fin

Weld gap shall not exceed 2.0% on total length of fin

Distance between 2 intervals (weld gaps) cannot be less than 150mm

Start and finish of the fin must be welded / tack welded

Length of the gap / weld discontinuity for a pipe:

5000 < L ≤ 10000 mm

Weld gap shall not exceed 2.0% per linear meters of fin

Weld gap shall not exceed 1.65% on total length of fin

Distance between 2 intervals (weld gaps) cannot be less than 200mm

Start and finish of the fin must be welded / tack welded

Length of the gap / weld discontinuity for a pipe:

L > 10000 mm

Weld gap shall not exceed 2.0% per linear meters of fin

Weld gap shall not exceed 1.5% on total length of fin

Distance between 2 intervals (weld gaps) cannot be less than 200mm

Start and finish of the fin must be welded / tack welded

Notes:

Applied laser welding technology provides a metrollogical bond between fin and surface of the pipe. This process ensures a continuous metallic connection of the fin material with pipe material and thereby improving heat transfer efficiency

The welding process provides a weld with full penetration (evaluation of the weld according to point 3 of this instruction)

The quantity of spatters has reduced to a minimum in comparison with fin tubes produced by GMAW method (MAG-Metal Active Gas) and HFW High Frequency Welding

In cases where these instructions do not cover a given regulation, VGB Power standards are valid: VGB PowerTech

The scope of test process:

Prior to production:

100% visual test of the materials

Macro test

Hardness test HV1 (HV5)

During production:

Continuous 100% visual exam

Every 100 finned tubes receives a macro test (additionally for material group 4, 5 and 6 hardness test)